To troubleshoot your Nissan NV200's electrical system, start by checking the battery voltage between 12.4V and 12.7V. Examine the alternator output, confirming it's within 13.8V to 14.2V. Inspect fuse box for continuity and verify all ground connections are solid. Use an OBD-II scanner to diagnose faulty sensors or ignition system components. Look for signs of wiring wear or corrosion, especially in harnesses and terminals. Address parasitic draws from aftermarket installations, and validate the remote start system is synced correctly. For in-depth diagnostics and step-by-step repairs, you'll uncover additional methods.

Key Takeaways

- Inspect battery voltage and alternator output for optimal levels to identify charging system issues.

- Check for damaged or corroded wiring harnesses to prevent electrical faults and ensure solid connections.

- Utilize an OBD-II scanner to diagnose and address malfunctioning sensors affecting engine performance.

- Verify the continuity and integrity of fuses and ground connections in the fuse box.

- Test the ignition switch, starter relay, and solenoid to troubleshoot ignition-related electrical problems.

Overview of Electrical Systems

The electrical systems in the Nissan NV200 are both complex and essential for the vehicle's operation. To guarantee peak performance, you must comprehend the core components and their functions. Start with the primary power source: the battery. It supplies the necessary voltage to the entire electrical system. You'll need to monitor voltage fluctuations closely, as inconsistencies can indicate underlying issues.

Additionally, consider the role of electronic key systems in the overall electrical architecture, as they integrate closely with many onboard components.

Next, pay attention to the alternator, which charges the battery while the engine runs. Inspect the alternator's output to ensure it's within the specified range, typically between 13.5 and 14.5 volts. Voltage fluctuations outside this range can lead to insufficient battery charging or overcharging, both of which can cause significant damage over time.

Focus on the wiring connections, which serve as the lifelines of your NV200's electrical system. Each connection must be secure to maintain electrical integrity. Use a multimeter to test for continuity in the wiring harnesses, ensuring there's no resistance that could impede current flow. If you find any corroded or loose wiring connections, replace or tighten them immediately.

You'll also need to examine the fuse box. Fuses protect the electrical system by breaking the circuit in case of a short or overload. Check each fuse for continuity and replace any that are blown. Ensure the fuse ratings match the OEM specifications to avoid potential electrical failures.

Lastly, address the vehicle's ground connections. A solid ground is essential for preventing voltage drops and ensuring stable operation. Clean any corroded grounding points and secure them tightly to the chassis.

Common Electrical Issues

Monitoring these core components is essential, but understanding common electrical issues in the Nissan NV200 will further enhance your troubleshooting abilities.

Wiring problems are a frequent culprit. Over time, wires can deteriorate or become damaged, leading to intermittent connectivity or complete circuit failures. Inspect the wiring harnesses meticulously, looking for frayed insulation, corrosion at connection points, or loose terminals. Utilize a multimeter to test for continuity across suspect wires, ensuring the integrity of the electrical path.

It's also important to be aware of the ignition system's components as they can also influence overall electrical health.

Sensor malfunctions are another pervasive issue. The NV200 relies heavily on various sensors to optimize performance and safety. For instance, the Mass Air Flow (MAF) sensor and Oxygen (O2) sensors are critical for fuel management and emissions control. A faulty sensor can trigger the Engine Control Unit (ECU) to log error codes, adversely affecting engine performance. Use an OBD-II scanner to read live data from these sensors, scrutinizing abnormal readings or discrepancies.

Additionally, relay failures can disrupt electrical systems. Relays act as switches for high-current circuits, like the starter motor or fuel pump. A malfunctioning relay can prevent these components from operating correctly. Test relays by swapping them with known good ones or using a relay tester to check for proper operation.

Moreover, ground connections are paramount in maintaining circuit integrity. A poor ground can cause erratic electrical behavior. Inspect and clean ground straps and terminals, ensuring a solid metal-to-metal contact.

Diagnosing Key System Failures

Diagnosing key system failures in the Nissan NV200 requires a methodical approach to isolate and pinpoint the root cause. Begin with key fob troubleshooting. Confirm the key fob battery is fully functional; replace it if necessary. Utilize a multimeter to measure the voltage, verifying it meets manufacturer specifications. If the key fob remains unresponsive, reprogram the key fob using the vehicle's onboard diagnostics (OBD-II) system or a specialized key programming tool. For more detailed guidance, consider consulting an ultimate guide on maintaining your Nissan NV200 key systems.

Next, address potential ignition switch problems. Insert the key and attempt to start the vehicle. If the ignition switch feels loose or fails to engage, it may be worn or damaged. Use a scan tool to check for Diagnostic Trouble Codes (DTCs) related to the ignition system. Inspect the wiring harness for continuity and any signs of wear or damage. Replace the ignition switch if necessary.

For remote start issues, verify that the remote start system is properly synced with the vehicle's control module. Validate the transmission is in 'Park' and the hood and doors are fully closed. If the remote start still fails, check the vehicle's security system for any triggered alarms or faults. Use a scan tool to access the remote start module and perform a functional test.

Keyless entry malfunctions can stem from a variety of sources. Begin by checking the keyless entry antenna and receiver module for proper operation. Use a signal tester to verify the transmission of signals between the key fob and vehicle. Inspect the vehicle's body control module (BCM) for any stored DTCs and reset the system if necessary.

Battery Drain Problems

After addressing key system failures, it's important to tackle battery drain problems, which can often be complex and multifaceted. You'll need to adopt a systematic approach to diagnose and rectify these issues effectively. Consider reviewing the smart key security features, as these may sometimes contribute to drain issues if malfunctioning.

First, make sure you've ruled out obvious culprits. Conduct a thorough battery replacement if the current one shows signs of age or wear. A deteriorated battery mightn't hold a charge, leading to persistent drain issues. Use a high-quality digital multimeter to measure the battery's voltage. A reading below 12.4V indicates a weak or failing battery, necessitating immediate replacement.

Next, evaluate the alternator's functionality, as it plays a critical role in maintaining the battery's charge. Perform alternator testing using a load tester. Attach the tester to the battery terminals and start the engine. The voltage should read between 13.8V and 14.2V when the engine is running. If it falls outside this range, the alternator might be underperforming or overcharging, thereby contributing to battery drain.

Following that, scrutinize the parasitic draw. Disconnect the negative battery terminal and connect a multimeter in series. With the vehicle off, the current draw should be below 50 milliamps. If it's higher, isolate the circuit by removing fuses one at a time until the draw drops to normal levels, pinpointing the problematic circuit.

Lastly, inspect accessories and aftermarket installations. Items like GPS units, alarms, or stereo systems can cause excessive drain if improperly installed or malfunctioning. Disconnect these devices one at a time to see if the drain subsides.

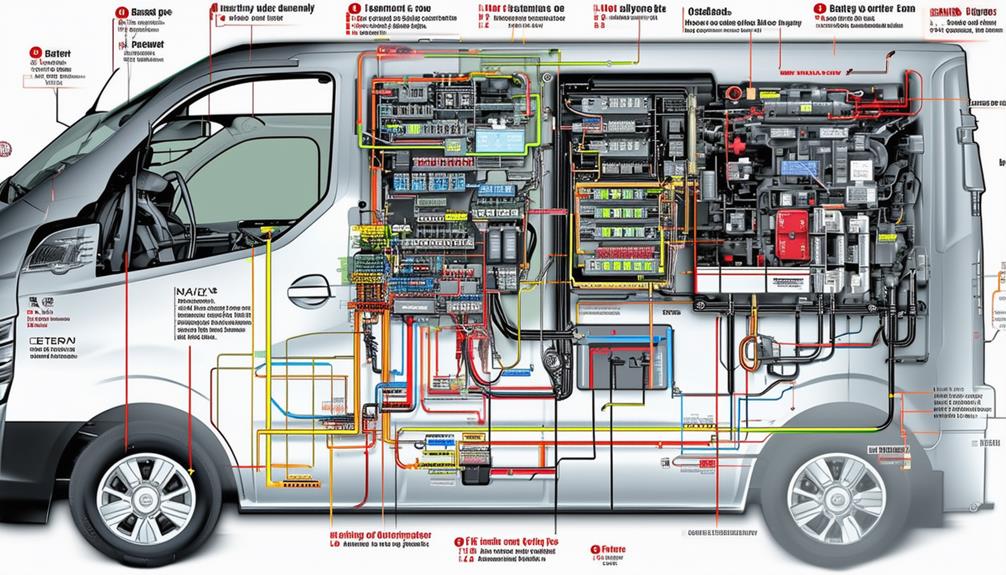

Fuse Box and Wiring Issues

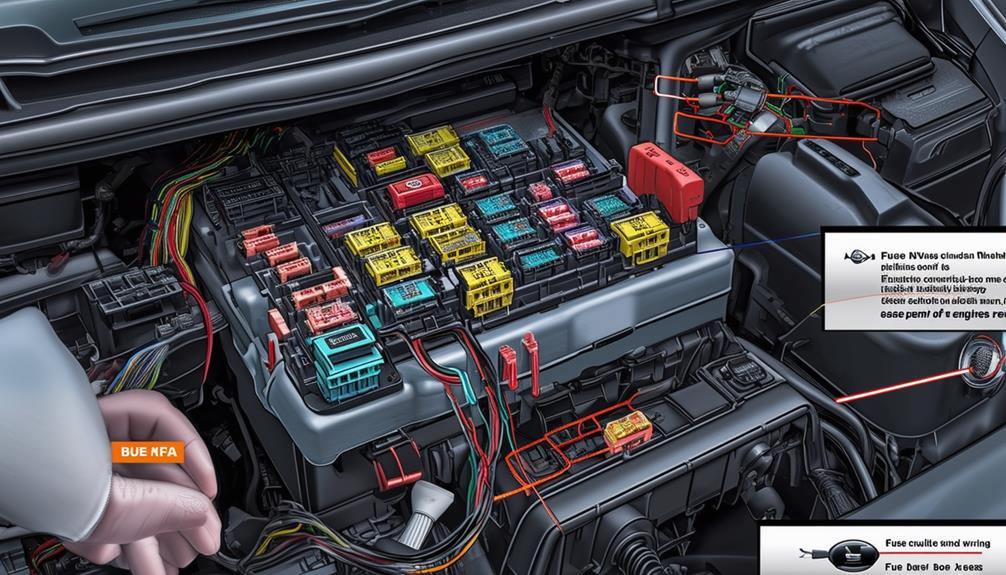

When addressing fuse box and wiring issues in the Nissan NV200, it's vital to methodically examine each component for potential faults. Start by disconnecting the vehicle battery to guarantee safety. Open the fuse box cover and use a multimeter to test each fuse for continuity. If any fuse fails the test, perform a fuse replacement with one of the same amperage. Regular maintenance can prevent many of these issues and guarantee long-term vehicle reliability.

Next, proceed with a thorough wiring inspection. Examine each wire for signs of wear, corrosion, or damage. Pay close attention to the connectors and terminal points, as these are common failure points. Utilize a wiring diagram to trace circuits and ensure you're inspecting the correct wires. If you detect any frayed or broken wires, replace or repair them using appropriate tools and techniques, such as soldering and heat shrink tubing. For more severe problems, professional, reliable service might be necessary.

Innovative diagnostic tools like OBD-II scanners can be invaluable during this process. Plug the scanner into the vehicle's diagnostic port to identify any fault codes related to electrical issues. These codes can guide you to specific areas within the fuse box or wiring harness that require closer examination.

It's also essential to inspect the grounding points. Poor grounding can lead to erratic electrical behavior. Clean and tighten all ground connections to guarantee a solid electrical path.

Malfunctioning Sensors

Malfunctioning sensors in the Nissan NV200 can create a wide range of issues from unpredictable engine behavior to inaccurate dashboard readings. For example, dashboard warning lights linked to key and security systems might occasionally be activated by sensor issues. To address this, initially identify the problematic sensor using an OBD-II scanner. Link the scanner to the diagnostic port and retrieve error codes, which will guide you to the malfunctioning sensor.

Once pinpointed, examine the sensor's wiring harness for any indications of wear, corrosion, or disconnection. Voltage variations frequently indicate a defective connection, so utilize a multimeter to measure the voltage across the sensor terminals. If the voltage readings are irregular, you've likely pinpointed the issue.

Subsequently, carry out a sensor replacement. Commence by disconnecting the battery to guarantee safety. Locate the sensor, which may be the oxygen sensor, MAF sensor, or another variety, and eliminate any retaining screws or clips. Delicately detach the electrical connector and remove the sensor from its housing.

Install the new sensor by reversing the removal steps. Confirm that the electrical connector is firmly secured to prevent future voltage fluctuations. Reattach the battery and erase any error codes using the OBD-II scanner. Initiate the engine and supervise the system. If the dashboard readings stabilize and engine behavior normalizes, you've effectively dealt with the malfunctioning sensor.

Troubleshooting Ignition Electrical Issues

Identifying and addressing sensor problems is a crucial part of maintaining the Nissan NV200, but ignition electrical issues can be equally disruptive. Begin by focusing on common ignition switch concerns.

Start by checking the ignition switch for continuity using a multimeter. Set the multimeter to the ohms setting and probe the switch terminals while turning the key through its positions. If the readings are inconsistent or show high resistance, replace the ignition switch.

Next, explore starting system diagnostics. Begin by inspecting the battery terminals for corrosion and verify a secure connection. Use a voltmeter to measure the battery voltage; a reading below 12.4 volts indicates a weak battery that needs charging or replacement.

Proceed to the starter relay and solenoid. Conduct a relay test by swapping it with a similar relay from another circuit. If the engine starts, the relay is defective. To test the solenoid, use a jumper wire to link the solenoid terminals. If the engine cranks, the solenoid is operational, and the issue lies elsewhere. For more advanced diagnostics, you might want to explore smart key technology as it can sometimes impact ignition systems.

For thorough troubleshooting steps, check the starter motor itself. Disconnect the battery and remove the starter. Bench-test by connecting the starter to a power source and observing its operation. If the motor fails to engage, replace it.

Preventing Electrical Problems

Proper upkeep is crucial to preventing electrical issues in your Nissan NV200. Begin by establishing a comprehensive maintenance checklist.

First, examine the battery terminals for corrosion; clean them using a wire brush and a mixture of baking soda and water. Confirm the battery voltage is within the manufacturer's specifications using a multimeter. Additionally, remember to inspect the key fob's features to guarantee it's operating correctly, as problems with the key fob can sometimes be mistaken for broader electrical issues.

Next, scrutinize all fuses and relays. Remove each fuse from the fuse box and test for continuity with a multimeter. Replace any defective fuses immediately. Preventive measures include checking the alternator's output. Use a multimeter to verify the alternator's voltage output falls within the ideal range of 13.8 to 14.2 volts.

Proceed to examine wiring harnesses. Look for indications of wear, fraying, or damage. Use electrical tape or heat-shrink tubing to mend minor issues; replace severely damaged wiring harnesses. Pay special attention to grounding points; loose or corroded grounds can cause various electrical issues. Tighten connections and clean with a wire brush and dielectric grease.

Remember the ECU (Engine Control Unit). A scan tool can assist you in checking for stored fault codes that might indicate emerging problems. Regularly update the ECU software to the latest version available from Nissan to ensure top performance.

Lastly, verify the operation of all sensors and actuators. Use a diagnostic tool to conduct a system-wide scan, identifying any sensor anomalies that could lead to future electrical malfunctions.

Repair Options

When addressing electrical system issues in your Nissan NV200, you have several repair options to take into account. Your first step is to diagnose the problem accurately. Once identified, you can choose between DIY techniques or professional services, depending on the complexity of the issue and your technical proficiency. Keep in mind that some advanced safety features, such as security sensors, may require specialized attention.

For minor issues, opt for DIY techniques. Start by consulting your vehicle's service manual to understand the electrical schematic. Utilize a multimeter to test voltage, current, and resistance across suspect circuits. Common repair solutions include replacing blown fuses, corroded connectors, or faulty relays. Make sure you use OEM replacement parts to maintain system integrity.

For instance, if you identify a faulty alternator, purchase a high-quality replacement unit to avoid future complications.

In cases where the problem lies beyond your expertise, professional services are advisable. Certified automotive electricians possess advanced diagnostic tools like OBD-II scanners that can uncover hidden faults within the ECM (Engine Control Module). They can also perform intricate repairs such as rewiring, sensor calibration, or ECU replacements. When selecting a service provider, verify their credentials and make certain they use genuine replacement parts to guarantee longevity and reliability.

Innovative repair solutions often involve upgrading existing components for enhanced performance. Consider installing advanced battery management systems or high-efficiency alternators. Such upgrades not only resolve current issues but also bolster your vehicle's electrical system against future failures.

Electrical System Maintenance Tips

Maintaining your Nissan NV200's electrical system guarantees durability and peak performance. For best results, implement preventive measures that address potential issues before they escalate. Begin with a thorough system maintenance routine, emphasizing regular inspection and component preservation.

Inspection and Maintenance Checklist

| Task | Frequency |

|---|---|

| Battery Voltage Check | Monthly |

| Alternator Output Test | Every 6 Months |

| Wiring Harness Inspection | Quarterly |

| Terminal Corrosion Cleaning | Every 3 Months |

Battery Voltage Check: Use a digital multimeter to verify that the battery voltage remains between 12.4V and 12.7V when the engine is off. Deviations indicate either overcharging or undercharging, requiring immediate attention.

Alternator Output Test: Conduct this test biannually with the engine running. Verify the alternator maintains an output between 13.8V and 14.2V. Fluctuations outside this range could indicate a failing alternator or voltage regulator, necessitating prompt replacement to avoid system-wide disruptions.

Wiring Harness Inspection: Examine the wiring harness for signs of wear, fraying, or corrosion every three months. Pay particular attention to areas near heat sources or moving components. Compromised wiring can lead to intermittent faults or complete system failures.

Terminal Corrosion Cleaning: Corrosion on battery terminals is a common issue behind electrical problems. Every three months, disconnect the battery and clean the terminals using a mixture of baking soda and water, followed by a thorough rinse and drying. Reconnect securely to ensure a strong electrical connection.

Frequently Asked Questions

How Can I Reset the Nv200's Electrical System?

To reset the NV200's electrical system, disconnect the battery for 10 minutes. This reset process can solve common issues like sensor malfunctions. Benefits include system recalibration, improved performance, and potential solutions to intermittent electrical faults.

What Are the Signs of a Failing Alternator in the Nv200?

You'll notice electrical warning signs like dimming headlights, flickering dashboard lights, or a dead battery. When these symptoms appear, consider an alternator replacement to maintain peak electrical system performance in your innovative NV200.

Can Aftermarket Accessories Affect the Nv200's Electrical System?

Absolutely, aftermarket accessories can wreak havoc on your NV200's electrical system. Compatibility concerns might cause voltage fluctuations, leading to erratic performance. Guarantee every added component meets the vehicle's specifications to maintain peak functionality and avoid catastrophic failures.

How Do I Check the Nv200's Voltage Regulator?

To check the NV200's voltage regulator, perform regulator testing by connecting a multimeter to the battery terminals. Start the engine and measure voltage output. Verify output stays between 13.5-14.5 volts under varying RPMs for proper regulation.

Are There Any Software Updates for the Nv200's Electrical System?

Greetings, tech-savvy auto enthusiast! To address your query, you'll need to check for software updates that mitigate voltage fluctuations. Visit Nissan's official site, enter your VIN, and download any available updates to enhance performance.

Conclusion

You've explored the intricacies of the Nissan NV200's electrical systems, understanding common issues, diagnosing failures, and addressing battery drain and fuse box woes. But here's the kicker—if you don't keep up with regular maintenance, you're setting yourself up for a cascade of electrical nightmares. Stay vigilant, follow each troubleshooting step, and don't ignore early warning signs. Your NV200's electrical health depends on it. Ready to tackle these challenges head-on? The road ahead awaits.