Did you know that nearly 30% of emergency exits inspected in Illinois fail to meet established safety standards? As a locksmith, your role in ensuring compliance with both the NFPA 101 Life Safety Code and local regulations is essential. You'll need to stay informed about the specifics of locking mechanisms, their functionality during emergencies, and the latest licensing requirements. Understanding these elements not only enhances your professional credibility but also plays an important part in public safety. So, what are the key standards you should focus on to uphold safety and security in your work?

Key Takeaways

- All lock installations must be compliant with the NFPA 101 Life Safety Code, ensuring safety during emergencies.

- Locks must allow for one-step egress operation without tools, crucial for rapid exit during emergencies.

- Compliance with local regulations, including proper height installation and accessibility standards, is essential for locksmiths.

- Locksmiths must undergo training, pass examinations, and maintain liability insurance to meet Illinois licensing requirements.

- Regular maintenance and servicing are vital for the safety and functionality of locking mechanisms in facilities.

Locking Mechanisms Overview

When evaluating locking mechanisms, it's essential to grasp the components and functions that contribute to their overall effectiveness. Lock cylinders are the heart of most locks, comprising fundamental parts like pins, the plug, and the shear point. Understanding these components enables you to identify how they interact during the locking process. Additionally, being aware of lock change laws is crucial for ensuring compliance during any servicing work.

Familiarity with terminology is indispensable. Each cylinder part serves a specific function; pins align at the shear point, allowing the plug to rotate when the correct key is inserted. Service malfunctions can arise from wear or improper installation, impacting the lock's performance. Recognizing common issues aids in proper maintenance and troubleshooting.

Keying methods, including master keying, are also significant. Different pin kits offer various solutions for managing multiple keys across a location while ensuring security. You'll want to understand each method's nuances to select the right one for your needs. Additionally, having a valid locksmith license is essential for employment in the industry, reinforcing the importance of regulatory compliance.

As you work with lock cylinders, precautions are necessary. Some locks require special handling due to their intricate designs or materials, which could affect your service approach.

Mastering the functions of key originating and code equipment enhances your skills, as does knowing how to produce keys accurately by code.

NFPA Compliance Standards

Understanding NFPA compliance standards is essential for ensuring safety in locking mechanisms used across various facilities. The NFPA 101 Life Safety Code outlines specific requirements that you, as a locksmith, must adhere to when installing or maintaining locking systems.

For instance, the locking and releasing means must allow for easy access without the need to open the door, ensuring a swift exit during emergencies. Releasing from the inside mustn't require a key, special tools, or even a passcode, highlighting the significance of quick and intuitive design. Additionally, locksmiths must also be aware of ADA compliance requirements to ensure that their locking systems accommodate individuals with disabilities.

Panic hardware plays a significant role in ensuring safety. Doors in egress paths need to operate with a single action—no keys or tools should hinder exit from the interior. This is especially important in assembly occupancies, where panic bars are mandated. Additionally, it's critical that proper exit door regulations are followed to guarantee sufficient egress options in times of crisis.

Furthermore, it's imperative that modifications to door hardware don't compromise fire door assemblies as per NFPA 80, ensuring fire resistance remains intact. The fire rating of doors must also be intact; any alterations can't reduce their fire protection capabilities.

Compliance extends to ensuring that doors resist smoke infiltration—even under conditions of fire exposure.

Finally, you'll also need to evaluate occupancy-specific requirements, particularly for high-hazard or educational facilities, necessitating regular inspections and emergency planning aligned with NFPA standards. Each of these elements contributes to a framework that safeguards lives and maintains freedom of movement in critical situations.

Security Locking Regulations

When implementing security locking regulations, you must guarantee egress compliance to facilitate safe exits during emergencies. The locking mechanism specifications are critical, as they determine how securely doors can be locked while still allowing for quick access. Balancing safety and security is essential to protect individuals without compromising their ability to evacuate swiftly. As the locksmith licensing requirements in Illinois evolve, it becomes even more important to ensure that all locksmiths are knowledgeable about these safety standards. Furthermore, understanding the importance of regulations helps locksmiths maintain the integrity of their services and build consumer trust. Additionally, locksmiths must stay informed about Illinois regulations for digital locks to ensure compliance when installing or servicing these advanced devices.

Egress Compliance Requirements

Egress compliance requirements in Illinois place a considerable emphasis on guaranteeing the safety of occupants in various facilities. It's essential to note that rekeying locks is one method to enhance security in rental properties, ensuring that only authorized individuals have access to them.

You're responsible for implementing proper exit facilities, assuring at least two exits on each floor used by residents. The exits must consist of enclosed interior stairways, exterior stairways, or horizontal exits.

Every resident's bedroom and common areas need to be within 100 feet of the nearest exit, extending to 150 feet only if there's a complete automatic sprinkler system.

You must also consider corridors and passageways, which can't lead through rooms that obstruct free passage. Their walls require a minimum one-hour fire-resistive rating.

Ensure no dead-end spaces exceed 20 feet in depth, while maintaining a corridor width of at least 36 inches for lower occupancy loads.

Different facilities, like residential buildings and assembly areas, have tailored egress requirements based on their specific situations.

Compliance hinges on regular inspections and enforcement by local officials and the Office of the State Fire Marshal, stressing the importance of fire safety regulations for overall building safety. Additionally, adherence to commercial lock standards is crucial for ensuring secure points of egress and protecting occupants in emergency situations.

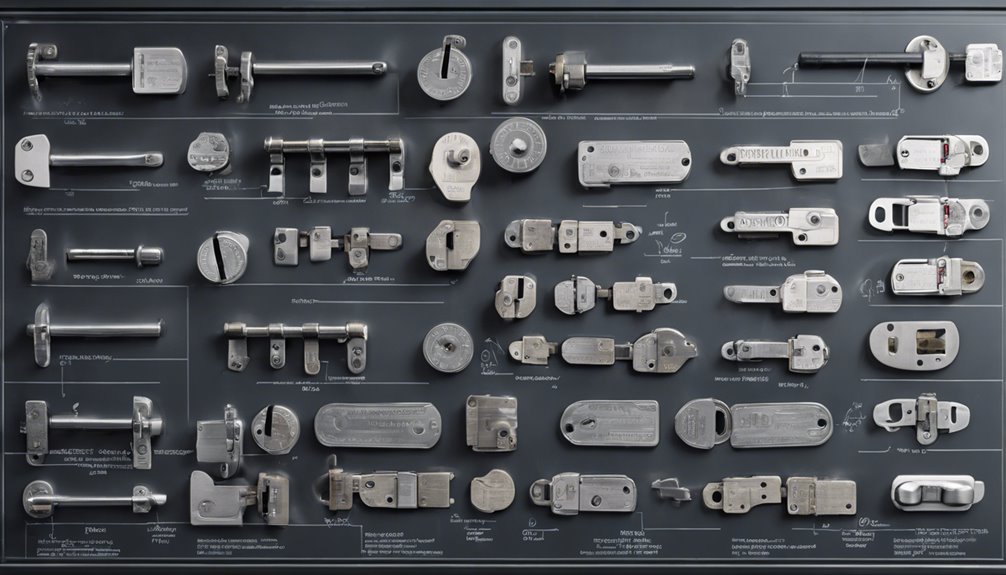

Locking Mechanism Specifications

Locking mechanisms in Illinois must meet stringent specifications to guarantee the safety and security of occupants. Your locks need to engage without requiring the door to open first and should release from the inside without a key or tool.

For remote engagement locks, it's vital that they remain accessible from the occupied side. Doors installed after July 1, 2019, must only allow one releasing operation, while those installed before that date may allow two. It is also essential to ensure that all locks comply with apprenticeship laws which train locksmiths in proper safety procedures.

Compliance with National Fire Protection Association's NFPA 101, Life Safety Code: 2015 Edition, is mandatory. Additionally, locks can't alter existing door-closing hardware related to fire safety.

Be aware that all employees must be trained in engaging and releasing the locking mechanisms, and local law enforcement needs access to disengage tools upon request.

Furthermore, hardware requiring specialized knowledge or tools to operate is prohibited, and bolt locks aren't allowed. The locks must be installed no more than 48 inches above the finished floor and need to be approved by local authorities. It's essential for locksmiths to stay informed about continuing education requirements to ensure compliance with evolving regulations.

Always verify replacement or new construction includes mortise locks or compliant alternatives to maintain these standards.

Safety and Security Balance

To guarantee a safe environment, it's vital to strike the right balance between security and accessibility in locking regulations. Emergency response planning must integrate proper training for staff on door security locking mechanisms.

Participation in drills is important, so everyone understands engagement and release methods from inside and outside. Keeping records of trained employees promotes accountability and compliance.

Locking means must conform to state and federal accessibility requirements, making sure no modifications hinder emergency equipment like panic hardware. Positioning these locks at a height no more than 48 inches accommodates individuals with disabilities, aligning with the Americans with Disabilities Act (ADA). Furthermore, locksmiths involved in evictions(Illinois eviction processes) need to be aware of these regulations to maintain compliance during lock changes.

Moreover, local law enforcement and fire departments should know how to disengage these locks during emergencies. This access requires that no special tools, knowledge, or credentials are necessary from inside the room.

New installations must adhere to simplified releasing processes—limited to one operation. For locks installed prior to July 1, 2019, the shift to one-operation releasing is vital during replacements. Additionally, locksmiths must be aware of their role in the eviction processes to ensure compliance during lock changes.

Balancing safety and security isn't just about compliance; it's about fostering an environment where freedom and protection coexist seamlessly.

ADA Lockset Requirements

When selecting locks for compliance with the Americans with Disabilities Act (ADA), it's important to understand the specific requirements that guarantee accessibility for all users.

First, locks must facilitate operation without tight grasping, pinching, or wrist twisting. Lever-style handles are common solutions, while push-activated controls like buttons and plates are acceptable, provided they require no more than 5 pounds of force.

It's vital to note that door mechanisms must adhere to the same force limit to guarantee usability for individuals with limited strength. You can measure this force with a Door Pressure Gauge (DPG). To achieve compliance, consider using compression seals or low-friction hardware to reduce operational force effectively.

The height and installation of operable parts play a significant role in ADA compliance as well. Install these components between 34 and 48 inches above the finished floor to guarantee reachability, especially for those in wheelchairs.

Make sure that the path to the operating hardware is unobstructed to avoid presenting barriers.

Documentation is key. You must verify that all locks offering access to public or shared spaces comply with ADA standards concerning operation, force, and height. Maintain records in the accessibility plan, including any electronic or automatic locks.

Regular checks and maintenance also help keep your installations aligned with ongoing ADA requirements. By adhering to these guidelines, you promote an environment of inclusivity and freedom for all users.

Locksmith Licensing Guidelines

Obtaining a locksmith license in Illinois requires meeting specific eligibility criteria and managing a structured licensing process. You must be at least 18 years old and demonstrate good moral character. It's essential that you don't have any alcohol, substance abuse, or narcotic addiction issues.

If you've been convicted of a felony, a minimum of ten years must have passed since your full discharge from the sentence. In addition, a dishonorable discharge from the armed forces disqualifies you.

To apply, you'll need to go through the Illinois Department of Financial and Professional Regulation (IDFPR). Your journey includes passing the qualifying locksmith licensing examination, completing a background check via fingerprinting, and paying the relevant application and licensing fees.

You also need to show proof of general liability insurance, which needs to be at least $1 million. While it's optional, completing an approved 20-hour basic locksmith training course is recommended.

You'll sit for the Locksmith Licensure Examination, which entails multiple-choice and true/false questions covering key origination, lock cylinder servicing, lock opening techniques, and basic electricity. If you've taken the ALOA examination within the past three years, those scores can be utilized for your license application.

Keep in mind that current licensing requirements could potentially change; they're scheduled to sunset in January 2029, potentially reducing the necessity for licensing going forward.

Technical Safety Specifications

Guaranteeing that locks and door assemblies adhere to established safety specifications is crucial for effective egress and fire protection. Exit doors should facilitate easy opening, requiring no more than one action. In assembly occupancies, panic bars are mandatory for swift egress. It's imperative that doors in the means of egress don't have locks or latches needing a key or tool for exit from the interior side; this allows unhindered escape during emergencies.

Moreover, door assemblies, including frames, must meet Illinois Fire Code standards, designed to withstand intense fire conditions. Materials for these assemblies should also comply with specified fire-resistance requirements, particularly in corridors serving over 30 occupants, which must have adequate life safety systems, including effective lighting and smoke control mechanisms.

In addition to the locking mechanisms employed, confirm they comply with both the Illinois Fire Code and relevant standards, particularly if the building utilizes a sprinkler system compliant with NFPA 13. This is crucial to avoid liability issues and maintain ADA compliance. Regularly servicing locks prevents malfunctions and enhances safety.

Understanding the installation and maintenance of exit doors can't be overstated. Follow the specific technical specifications for installation, and make diligent effort in maintaining door locks, closers, and panic hardware.

Regular lubrication and repairs are critical, as is meticulous record-keeping of all maintenance actions. By adhering to these technical safety specifications, you greatly contribute to both safety and compliance in your installations.

Emergency Egress Considerations

When considering emergency egress, you need to guarantee that doors meet specific requirements, such as proper panic bar applications and compliance with ADA guidelines.

These factors are critical not only for efficiently facilitating a safe exit but also for accommodating individuals with disabilities.

Egress Door Requirements

Egress door requirements play a significant role in emergency evacuation, as they must be designed for swift and safe exit from buildings during crises.

To guarantee effective egress, you need to evaluate the following key elements:

- Easy Operation: Doors must be easy to open without any keys or tools from the interior side.

- Outward Swing: Doors should swing outward to facilitate quick evacuation in emergencies.

- Smoke and Fire Resistance: Exit doors must resist smoke infiltration and meet fire exposure standards.

Incorporating these features into your locking systems is essential for compliance with NFPA 101, the Life Safety Code.

You should also note that the releasing mechanism must be accessible—no higher than four feet off the ground and operable without special knowledge or devices.

Regular inspections are important to maintain compliance with the Illinois Fire Code and local regulations.

Be mindful of special conditions in certain facilities, like healthcare settings, where unique locking arrangements might be necessary.

Panic Bar Applications

Effective emergency evacuation not only relies on properly designed egress doors but also on the integration of panic bars, a crucial component in many facilities.

These devices, indispensable for safety, must comply with the International Building Code (IBC) and the National Fire Protection Association's Life Safety Code (NFPA 101). You'll encounter panic bars in Assembly, Educational, and High Hazard occupancies that have 50 or more occupants. They must be installed on the egress side of doors that swing outward, constructed from durable materials like stainless steel or heavy-duty aluminum.

When choosing panic bars, verify they operate with no more than five pounds of force. Additionally, no locking device can override latch release when the bar is engaged.

Compliance checks should include local regulations, as these might introduce specific adjustments to national standards. Regular inspections are essential to confirm that the devices function correctly and meet safety standards.

Adequate signage is necessary to guide occupants toward emergency exits, confirming they can evacuate swiftly during a crisis. Remember, these measures promote safety while balancing security concerns for unauthorized access.

ADA Compliance Necessities

Although guaranteeing safety is paramount, ADA compliance remains a crucial aspect of emergency egress planning. For any building design, you must prioritize accessible means of egress to make sure everyone can escape safely during an emergency.

Here are key considerations you should follow:

- Confirm at least two means of egress from all spaces, and for larger occupant loads, the requirements increase—three for 500 or more, and four for 1,000 or more.

- Ensure doors swing outward and can be operated with one action, allowing quick access without tools or keys.

- Install tactile and visual "EXIT" signs according to ADA Standards, guiding individuals to accessible egress routes.

In addition, locking mechanisms must comply with the National Fire Protection Association's standards, allowing immediate release in emergencies.

Automated doors need maneuvering clearance on the egress side unless equipped with necessary backup systems. Regular inspections are essential to maintain ongoing compliance with fire codes.

Specialized Facility Challenges

In specialized facilities, addressing unique security challenges is essential to maintaining safety and functionality. As a locksmith, you'll encounter various locking devices, from combination locks to dual locking mechanisms, often integrated within safes, vaults, and cabinets. Your expertise in troubleshooting these security units is critical. You must quickly assess malfunctioning components and possess an in-depth understanding of each lock's internal structure and operating characteristics.

Establishing efficient master key coding systems is another significant challenge. You'll need to guarantee compatibility by consulting manuals that specify keyway requirements. Analyzing building blueprints will help you determine the total number of locks and identify those that can be keyed alike. Arithmetic skills are important in this process for establishing pin sizes and guaranteeing overall compatibility across different locking devices.

The physical demands of your work can't be overlooked. Using standard and power tools, alongside electric drills and acetylene torches, poses risks, including cuts and bruises. Precision is paramount; drilling or burning without damaging the lock's contents is a task that requires focus and skill.

Moreover, adhering to Illinois licensing and training regulations is mandatory. Completing an approved training course, passing a state examination, and undergoing a criminal background check are all part of achieving compliance. Carrying ID cards while in the field guarantees both professional credibility and adherence to Life Safety regulations.

Understanding these specialized challenges is essential for delivering effective locksmith services in today's demanding environments.

Frequently Asked Questions

What Types of Locks Are Preferred for Residential Properties?

For residential properties, you should consider deadbolts and deadlocking latches as preferred locking options.

Deadbolts offer strong security with at least a one-inch bolt projection, while deadlocking latches guarantee secure closure with a half-inch projection.

Make certain locks can be easily operated from the inside without a key.

Additionally, enhance your security by incorporating viewing devices and guaranteeing compliance with accessibility standards, allowing for safe and convenient entry for all occupants.

How Often Should Lock Inspections Be Conducted?

Did you know that about 30% of residential break-ins occur through unlatched doors?

It's essential to conduct lock inspections regularly, ideally every six to twelve months. Consider increasing frequency for high-traffic doors or after security incidents.

If you've recently changed staff or experienced a security breach, check those locks immediately. Confirm they're functioning smoothly, as a well-maintained lock can greatly enhance both security and peace of mind in your home.

Are There Specific Locks for High-Security Areas?

Yes, specific locks are designed for high-security areas.

You'll want to choose high-security deadbolts and locks that meet strict ANSI/BHMA standards. These locks resist picking, drilling, and other forced entry methods, ensuring your sensitive materials are well-protected.

Additionally, features like key control and advanced materials enhance security.

When selecting locks, consider the security needs of the area and opt for solutions tailored to withstand the unique challenges that high-security environments present.

Can Smart Locks Comply With NFPA Standards?

Yes, smart locks can comply with NFPA standards, provided they meet the required safety criteria.

You'll want to verify that these locks are listed according to ANSI/UL 294, allow for internal opening without special knowledge, and integrate seamlessly with fire safety systems like alarms and smoke detectors.

What Training Is Available for Locksmiths on New Locking Technologies?

When you're diving into the world of new locking technologies, you'll find a treasure trove of training opportunities.

Consider hands-on sessions for smart locks, which teach installation, programming, and servicing. There's also guidance on integrating access control systems and biometrics.

Equally important, ALOA's distance-learning options and resources cater to your growth in this dynamic field, ensuring you stay ahead of the curve while enjoying the freedom and flexibility in your craft.

Conclusion

In conclusion, understanding Illinois safety standards for locks is essential for your success as a locksmith. By staying compliant with NFPA guidelines and local regulations, you guarantee the safety and security of your clients. Don't cut corners when it comes to inspections and maintenance, especially in high-hazard facilities. Staying abreast of licensing requirements will keep you ahead of the game, allowing you to provide excellent service. Remember, in this business, it's always best to be one step ahead.