To avoid common installation mistakes, guarantee correct wire connections by observing polarity and using wire connectors properly. Prioritize workspace safety by keeping it clutter-free and maintaining clear areas around circuit breakers. Adequate lighting enhances visibility and reduces errors, while prioritizing safety measures like turning off power at circuit breakers and wearing protective gear is essential. AC installation errors, such as improper sizing or vent placement, can lead to inefficiencies. Accurate window measurements and precise installation techniques prevent drafts and energy loss. Following these tips will help you guarantee a successful and safe installation process with peak performance.

Key Takeaways

- Proper wire connections prevent hazards and malfunctions.

- Adequate lighting enhances visibility and reduces errors.

- Clear workspaces prevent accidents and ensure safety.

- Regular inspections of connections ensure functionality.

- Following safety measures prevents injuries and fires.

Planning Adequate Project Time

When initiating any installation project, the vital factor that often determines success is the adequate planning of project time. Rushing through a project increases the likelihood of errors, such as incorrect wiring or improper material handling, which can lead to costly repairs.

It's essential to allocate sufficient time for troubleshooting and addressing challenges that may arise during the installation process. Complex projects, especially those involving security installations, require detailed planning to avoid common security installation mistakes. Additionally, understanding the differences between wireless and wired systems can help in better preparation and execution.

To avoid installation errors, guarantee you have a clear timeline that includes a buffer for unforeseen circumstances. Allocating at least 10-20% of your total project time for unexpected issues can greatly enhance the success of your installation.

Proper time management is key to executing correct installation methods and delivering high-quality outcomes. By planning adequate project time and allowing room for adjustments, you can mitigate risks, prevent mistakes, and guarantee a smooth installation process.

Securing Work Area Properly

You must prioritize clearing workspaces safely and organizing tools effectively to minimize risks during installations.

Keeping your work area clutter-free and tools accessible can greatly reduce accidents and enhance efficiency.

Remember to maintain a safe distance from flammable materials and guarantee clear access to electrical panels for a secure and efficient work environment.

Clearing Workspaces Safely

To guarantee a safe installation process and minimize the risk of accidents, securing the work area properly is essential. When setting up your home security system or tackling any DIY installation tasks, ensuring a clutter-free workspace is vital.

Over 80% of electrical fires occur in residential buildings, emphasizing the need for a secure work area. Clear areas around circuit breakers and electrical panels to prevent obstructions during emergencies. Maintain a safe distance from flammable materials to reduce fire hazards.

Regularly inspect and tidy your workspace to promptly address any potential safety hazards. By organizing your tools and materials efficiently, you not only prevent accidents but also make your work more manageable.

Organizing Tools Effectively

Guarantee ideal safety and efficiency by organizing your tools effectively in the workspace. Store all tools in designated areas to minimize clutter and reduce the risk of accidents.

Keep frequently used tools within arm's reach, organizing them for easy identification and access to improve installation efficiency. Utilize toolboxes or organizers with compartments to prevent tangling, saving time during critical moments.

Maintain a clean work area by regularly removing unnecessary materials and debris to prevent electrical fires. Designate a specific, clearly marked area for hazardous materials to avoid accidental exposure or injuries.

By following these practices, you not only create a safer environment but also streamline your work process. Stay organized, keep your tools accessible, and prioritize a tidy workspace to enhance your efficiency and safety during installations.

Your dedication to organization will benefit not only yourself but also those you serve.

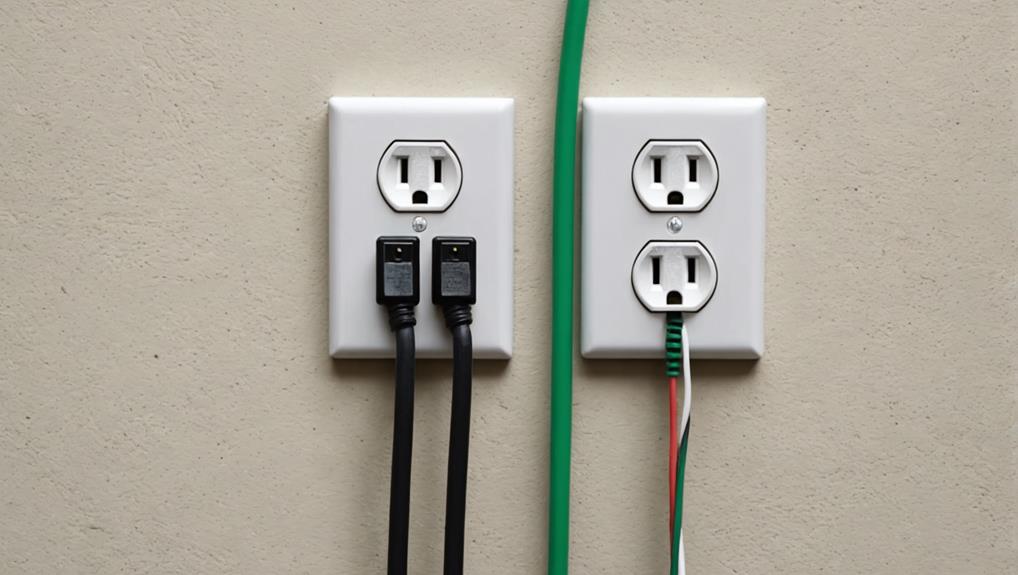

Correct Wire Connections

When dealing with electrical installations, guaranteeing correct wire connections is essential to prevent potential hazards and malfunctions.

Always remember to observe polarity by connecting red wires to red terminals and black wires to black terminals to avoid electrical issues. If you notice flickering lights or tripped breakers, it could signal incorrect wiring. In such cases, immediately turn off the power at the circuit breaker, double-check all connections, and only restore electricity once everything is verified.

Prioritize safety by using wire connectors properly and guaranteeing they're securely fastened to prevent overheating or fires caused by loose connections. Before completing the installation, regularly inspect and test all connections to confirm everything is working as intended and to prevent future problems.

Working in Sufficient Light

For ideal effectiveness in your electrical installations, guaranteeing you work in sufficient light is paramount.

Working in poorly lit conditions increases the chances of missing critical details, leading to costly mistakes and rework. Adequate lighting is essential as it enhances visibility and reduces errors like incorrect wiring connections.

You can improve safety and accuracy by using portable lights or collaborating with someone to provide extra lighting. Whenever possible, try to work during daylight hours to benefit from natural light, reducing reliance on artificial sources and minimizing eye strain.

Well-lit tools and workspaces are vital to prevent accidents and guarantee all components are visible and easily accessible during the installation process.

Prioritizing Safety Measures

To guarantee your electrical installations proceed smoothly and safely, prioritizing safety measures is key.

Before starting any work, always remember to turn off the power at the circuit breakers. This simple step can prevent electric shock and guarantee your personal safety.

Additionally, wearing rubber gloves and protective clothing when handling electrical components and tools can minimize the risk of injury.

Keeping your workspace organized is vital as over 80% of electrical fires in residential buildings stem from unsafe work areas.

Regularly reviewing and adhering to safety guidelines and local codes is essential to guarantee compliance and reduce the likelihood of accidents during installation.

Using the appropriate tools for electrical tasks, such as wire strippers and insulated tools, not only enhances safety but also improves efficiency throughout the installation process.

Organizing Wires Effectively

Efficiently organizing wires is essential to ensuring a smooth and error-free installation process. To achieve this, follow these key steps:

1. Wrap Each Set Separately: Prevent tangling by using zip ties or clips to wrap each set of wires individually. This method allows for easy identification and access during installation, saving you time and frustration.

Additionally, make sure to keep wires away from any sharp edges or heat sources to avoid accidental damage.

2. Color-Code Wires: Organize wires by color according to their function. For example, use red for power and black for ground. This simple practice helps avoid confusion and reduces the likelihood of mistakes.

Consult best practices for further guidance on color-coding standards.

3. Maintain a Designated Workspace: Keep your workspace tidy and organized to prevent clutter. A clear area not only reduces the risk of accidents but also minimizes errors during installation.

4. Regularly Check Organization: Throughout the project, make sure to inspect wire organization. By doing this, you can catch any new tangles or knots early on, preventing potential issues during troubleshooting later.

Remember to store wires in labeled containers when not in use. This protects them from damage and makes it easier to find specific wires when needed.

AC Installation Mistakes to Avoid

When installing your AC system, be sure to place the thermostat correctly to avoid inaccurate temperature readings and discomfort.

Proper sizing of your unit is essential for maintaining energy efficiency and desired comfort levels.

Additionally, guarantee vents are strategically placed to prevent hot and cold spots in your indoor space.

Thermostat Placement Accuracy

Improper placement of your thermostat during AC installation can lead to significant issues with temperature accuracy and system efficiency.

Incorrect positioning can result in inaccurate temperature readings, causing inefficient cooling cycles and increased energy costs. To guarantee ideal performance, remember these key points:

- Central Location: Install the thermostat away from direct sunlight, drafts, or heat sources for accurate temperature sensing.

- Avoid External Influences: Place the thermostat away from doors or windows to prevent it from reacting to external temperatures, which can lead to unnecessary HVAC cycling and discomfort.

- Mounting Height: Position the thermostat at eye level, around 5 feet off the ground, for better performance.

- Regular Maintenance: Check and recalibrate the thermostat settings regularly post-installation to maintain accurate indoor temperature readings and system efficiency.

Proper AC Sizing

To guarantee peak performance and energy efficiency of your air conditioning system, proper AC sizing is paramount. An undersized unit will struggle to cool your space effectively, leading to short cycling and increased energy costs.

Conversely, an oversized unit can result in inefficient cooling cycles and higher humidity levels. Determining the right AC size involves considering the square footage of the space, insulation quality, and local climate.

Utilizing a Manual J calculation can help accurately assess your cooling needs. While a general rule of thumb suggests allocating 20 BTUs per square foot of living space, adjustments may be necessary for factors like ceiling height and window exposure.

Incorrectly sized AC units can void warranties and lead to higher long-term costs due to increased wear and tear on the system. By consulting with a professional HVAC technician, you can guarantee proper sizing that takes all relevant factors into account for peak performance and energy efficiency.

Vent Placement Importance

Avoiding common installation mistakes is vital for optimal AC performance. When it comes to vent placement, overlooking this significant aspect can lead to discomfort and inefficiencies in your home cooling system.

Here's how you can secure ideal vent placement:

- Prioritize Airflow: Position vents strategically to promote proper airflow and prevent hot and cold spots.

- Avoid Obstructions: Keep vents clear from furniture and decor to maintain efficiency and consistent cooling throughout the space.

- Consider Room Size: Tailor vent placement to room sizes and usage to guarantee adequate cooling and air distribution.

- Regular Maintenance: Inspect and adjust vent locations as needed to accommodate changes in room layout and maintain ongoing comfort and efficiency.

Importance of Proper AC Installation

When it comes to guaranteeing your air conditioning system operates at its best, proper AC installation plays an essential role. Ideal performance and energy efficiency are achievable through correct installation, creating a comfortable indoor environment and considerably reducing utility costs.

Inadequate installation can result in inefficient cooling cycles and increased wear on the unit, potentially shortening its lifespan and leading to higher repair expenses. Incorrect refrigerant levels during installation may cause leaks and inefficiencies, resulting in costly repairs and reduced system reliability.

Following manufacturer specifications during installation is vital to maintain warranty coverage, guarantee compliance with safety standards, and meet local codes.

Regular post-installation inspections of ductwork and insulation help maintain air quality and system efficiency, preventing energy loss through gaps and leaks.

Prioritizing proper AC installation not only enhances performance but also contributes to long-term cost savings and a more reliable cooling system.

Window Measurement Errors

When measuring for windows, accuracy is key to avoid issues like drafts and poor fitting.

Make certain to take into account the thickness of your interior walls to determine the correct jamb width needed for a proper installation.

Consistency in window selection and adherence to manufacturer guidelines are essential to guarantee a seamless fit and ideal performance.

Proper Window Sizing

To guarantee proper window sizing and avoid common installation mistakes, it's essential that accurate measurements of the window openings are taken. Here are some key points to take into account when sizing windows:

- Precision is Key: Verify accurate measurements to prevent issues such as drafts, leaks, and energy inefficiency in your home.

- Prioritize Standard Sizes: Opt for standard window sizes whenever possible to reduce ordering errors, but take into account custom options for unique openings.

- Mind the Jamb Width: Factor in the thickness of your walls to determine the appropriate jamb width for a snug fit and structural integrity.

- Seek Professional Advice: Consistency in window height and placement is vital for aesthetic appeal, so consult experts for precise measurements and installation to avoid costly mistakes.

Accurate Jamb Measurements

To guarantee your window installation progresses smoothly, paying attention to accurate jamb measurements is paramount. The thickness of interior walls directly impacts the needed jamb width, assuring a proper fit within the rough opening.

Neglecting jamb width considerations can result in ill-fitting windows, leading to air leaks and potential structural issues that compromise energy efficiency. When ordering windows, refer to manufacturer guidelines for jamb sizing to prevent installation errors and assure compliance with building codes.

Opting for standard window sizes reduces the risk of ordering mistakes, but for non-standard dimensions, custom millwork windows may be necessary, highlighting the significance of precise measurements.

Make certain to employ proper measurement techniques, such as checking for level and square during installation, to uphold the aesthetic integrity and functionality of the window installation.

Window Installation Techniques

Proper window installation techniques are vital for guaranteeing ideal performance and longevity of your windows. To achieve this, follow these key steps:

- Accurate Measurements: Take precise measurements of the window opening to prevent drafts and energy loss. Standard sizes can reduce errors, but for custom sizes, consult a professional to avoid mistakes.

- Proper Placement: Confirm windows are level, plumb, and square for correct installation. This prevents insulation issues and structural problems that could arise from improper positioning.

- Weather-Resistant Barrier: Use a well-adhered barrier to prevent air and moisture infiltration. Gaps in barriers lead to energy loss and increased bills, making this step vital for efficiency.

- Compliance and Safety: Adhere to local building codes and manufacturer instructions. This not only avoids fines but also guarantees safety and maintains your window warranty.

Frequently Asked Questions

What Are the Mistakes on AC Installation?

When installing an AC, you might place the thermostat incorrectly, leading to inaccurate readings.

Improperly sized units could struggle to cool efficiently.

Poor vent placement may create hot and cold spots, affecting comfort.

DIY errors, like wrong refrigerant levels, can raise long-term costs.

Mishandling refrigerants can cause leaks and damage.

Be cautious during installation to guarantee your AC works effectively and efficiently, maintaining a comfortable environment for your space.

What Is a Common Mistake in Ductwork Installation?

When installing ductwork, a common mistake is improper sizing, which can decrease airflow and make your heating or cooling system work harder.

This leads to inefficiency and higher energy bills.

Make sure to size your ducts correctly to guarantee proper airflow and system performance.

Conclusion

Avoiding common installation mistakes is essential to ensuring the success and safety of your project. By properly planning, securing the work area, making correct wire connections, working in sufficient light, prioritizing safety measures, and avoiding AC installation errors, you can save time and money in the long run. Remember to measure windows accurately and use proper installation techniques to prevent any future issues. Take the time to do it right the first time and enjoy the benefits of a well-installed project.